SMAC INDUSTRIAL AIR CLEANER

Designed specifically for the harsh environment found in and round steel mills.

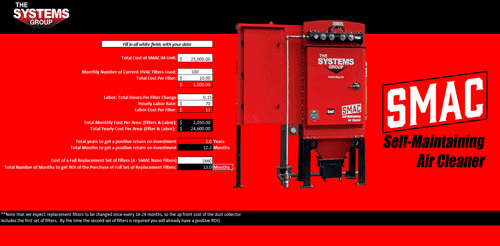

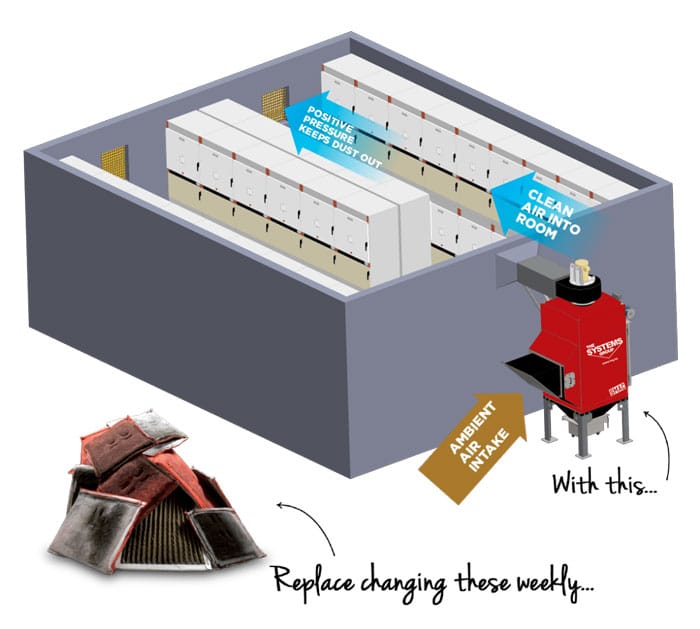

The SMAC industrial air cleaner was designed specifically for the harsh environment found in and around steel mills. Traditional room filtration involves a bank of HVAC filters that need to be changed on a weekly or even daily basis to ensure the mill’s equipment remains protected from conductive dust. The SMAC unit will not only provide a cleaner area for your critical spaces, but it also takes out the weekly/daily changing of filters and the labor costs that go along with that. SMAC units are self-maintaining with a filter life of 2-4 years!

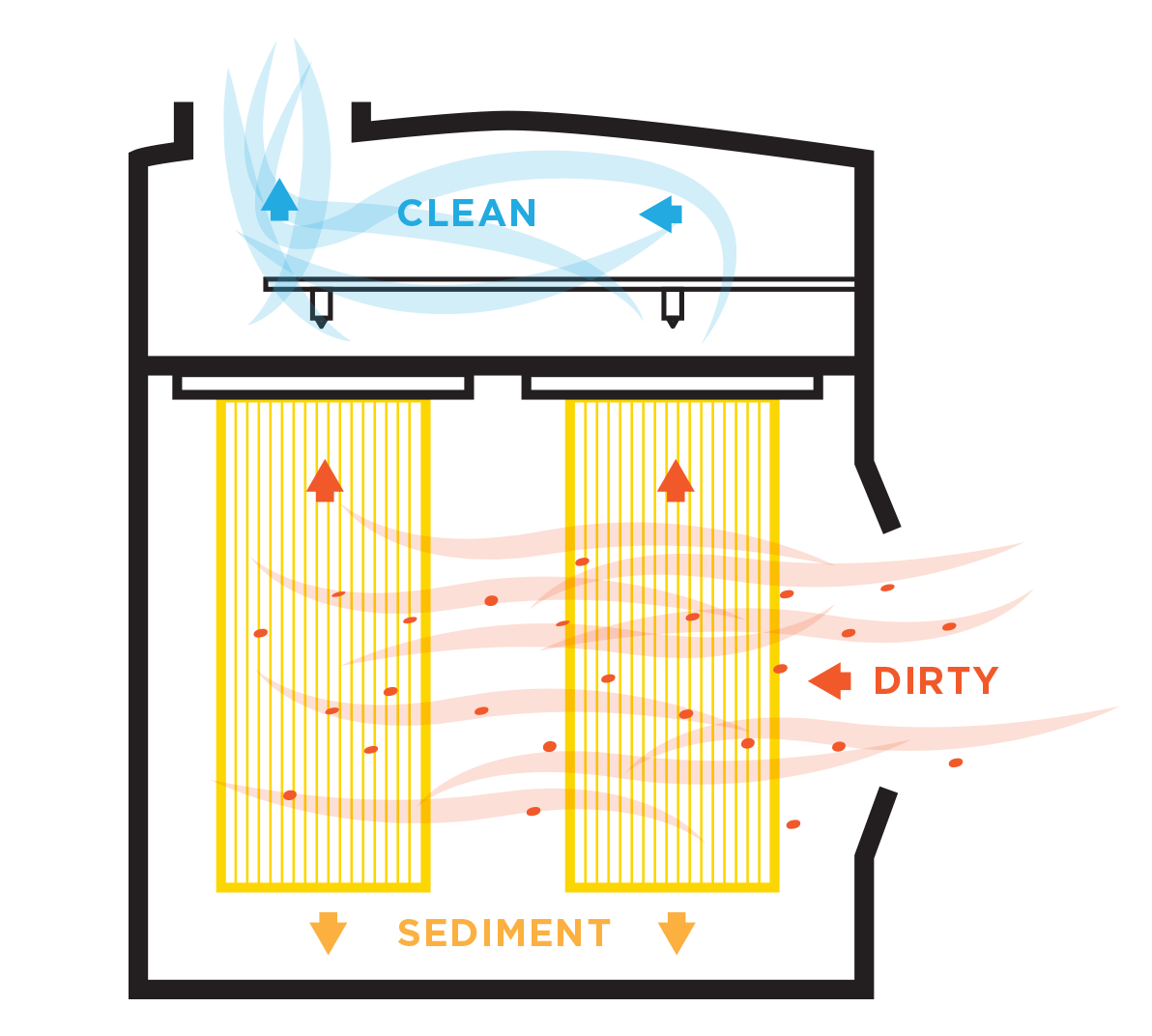

While the SMAC can cover a variety of applications, there are two core concepts on how it works: Room Pressurization & Dust Collection

How the SMAC Industrial Air Cleaner Works:

Dirty air is pulled in from duct work or ambient air intake and particulates are captured by the SMAC filters. The clean air is pulled through the filter media and up into the clean air plenum. The air then exits the SMAC unit and goes to the return air duct. Compressed air pulses down into the filter automatically cleaning it from the inside out. The dust cake built on the filter is then knocked down into the grating below or into a hopper.

Room Pressurization

Dust Collection

Room Pressurization Applications

Dust Collection Applications

1000x THE LIFE OF TRADITIONAL HVAC FILTERS

BETTER THAN HVAC

Traditional HVAC filters just aren’t built to handle the heavy dust loads found in and around steel mills. This leads to many mills requiring a full-time maintenance crew purely to change out filters weekly or sometimes even daily throughout the facility.

The SMAC industrial air cleaning system will not only provide a cleaner area for your critical spaces, but it also takes out the weekly/daily changing of filters and the labor costs that go along with that. SMAC units are self-maintaining with a filter life of 2-4 years!

SAFETY IS JOB ONE

PROTECTING PEOPLE & EQUIPMENT

Keeping Critical Spaces Clean

Dust Hazards in the Steel Mill

Electric arc furnaces in steel mills produce dust made up of a variety of different metals and other materials. Many of these materials are harmful to human health. These dusts present a health risk to anyone who has to work in areas such as operator pulpits where dust levels are high. In enclosed spaces like transformer vaults, motor control center rooms or other electrical rooms; conductive metal dusts can cause an arc flash hazards. All critical spaces require an extra level of protection from harmful dusts.

Health Risks from Steel Mill Dust

Steel mills produce metal dust that contains a mixture of large and small particles. The exact components of the dust depends on the type of steel and the process. In general, the most common metal is iron, followed by carbon, lime, zinc, manganese, calcium, and silicon, but the dust often includes metals such as lead, arsenic, and cobalt which are highly toxic1. The Material Safety Data Sheet for steel mill electric arc furnace dust warns that inhalation can cause allergic reactions, cancer, lung damage, weakness, personality changes, kidney damage, and problems with the brain and nervous system.

“Since purchasing 12 of the SMAC Air Compressor Filter Units, I have saved close to $90,000 on filter cost over the first 6 months of use.”

-Steel Mill Air Compressor Maintenance Supervisor

PLACE INSIDE OR OUTSIDE YOUR MILL

EASY TO INSTALL

SMAC units are easy to install and can be placed inside your mill, outside your mill, or even on the roof!

It’s as simple as: