HOSPITAL GRADE CLEAN AIR FOR AIR COMPRESSOR INTAKES

PREVENT DAMAGED EQUIPMENT

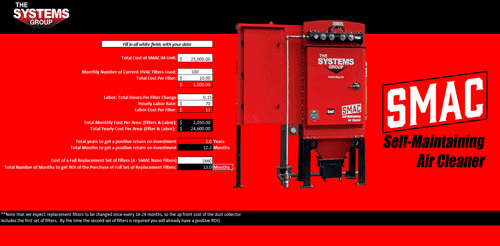

Managing air compressor intakes can be a full-time job with constant filter change-outs. Moreover, if too many dust contaminants get in the system, it can turn into a compounding, very expensive problem. But SMAC units relieve your headache, reducing contract labor using Self-Maintaining technology.

Most importantly, the SMAC unit uses blasts of compressed air to periodically clean your filters. It does this on-demand, as needed based on dust load, or on a schedule. As a result, there is longer (1000x) filter life and less maintenance than traditional HVAC air filtration systems.

Traditional Air Compressor Intake

Cleaner Air Compressor Intakes Plus Room Pressurization

While the primary function is to supply clean air directly to the compressor’s intake, using SMAC has another benefit. It can also pressurize an air compressor room at the same time to prevent dust from entering it. The clean environment further protects the equipment as well as maintenance personnel.

HVAC systems by themselves are insufficient to protect an industrial air compressor in a room. They will certainly maintain the room temperature, but not keep damaging dust out. Steel mills usually attempt to filter, cool, and pressurize a compressor room with only an HVAC system. They draw ambient air into the room from outside, typically with MERV 12 or 14 filters. However, dust can go right through those filters.

Further, just producing airflow through the room with an HVAC system creates no pressurization in it. For instance, there’s a common way of reducing the heat from the compressor. That’s by letting it exit through a vent on the other side of the room. But the misbelief is that this also creates positive pressure. The fact is, this will not prevent dust from blowing in through an opened door.

On the other hand, the SMAC nanofiber filter captures all particles with an efficiency of 0.5 micron and larger. We design the system to keep enough pressure in the room so that a sufficient amount of air flows out an open door to keep dust and contaminants out. So, we’re pressurizing the room with clean, filtered air using SMAC technology rather than the old, inadequate way with just an HVAC system.

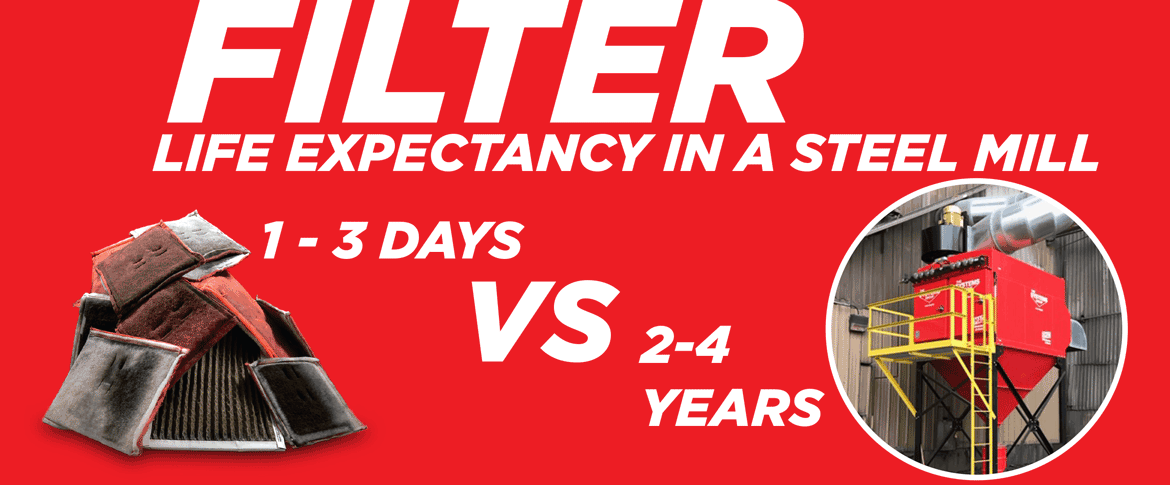

Proper filtration will extend the life of the compressor. To that end, HVAC filters cannot handle the heavy dust loading and particle sizes like a SMAC filter system can.

Common HVAC Filter Housing Arrangement

Dust loads up these disposable filters in only a few days with this typical setup. Consequently, they require continual filter replacement.

SMAC for Air Compressor Intakes

SMAC unit with self-cleaning filters supplies clean air to the intake of an industrial air compressor in a steel mill. As a result, constant HVAC filter replacement is eliminated.

Project Photos for Air Compressor Intakes

“Since purchasing 12 of the SMAC Filter Units for our air compressor intakes, I have saved close to $90,000 on filter cost over the first 6 months of use.”

-Steel Mill Air Compressor Maintenance Supervisor