OEM Replacement Dust Collector Cartridge Filters

Performance Upgrade Dust Collector Cartridge Filters for Your Existing System Brand

Need replacement dust collector cartridge filters for your existing brand, but want better performance? SMAC That! SMAC cartridge filters are available in sizes and styles to fit all makes and models of industrial dust collectors.

They can be used on any application, room pressurization, or manufacturing process that requires dust, smoke, or fume extraction. We also offer HEPA filters for secondary filter banks in applications that require it.

Does your dust collector have vertical filters like Camfil Farr units or horizontal filters like Donaldson Torit? Then we have SMAC high-efficiency replacement cartridge filters that fit and improve your system at a competitive price.

Our OEM replacement filters bring SMAC efficiency and capacity to the system that you’re currently running in your shop.

SMAC Filter Options

Nano Filters

Nano FR Filters

Spunbond Filters

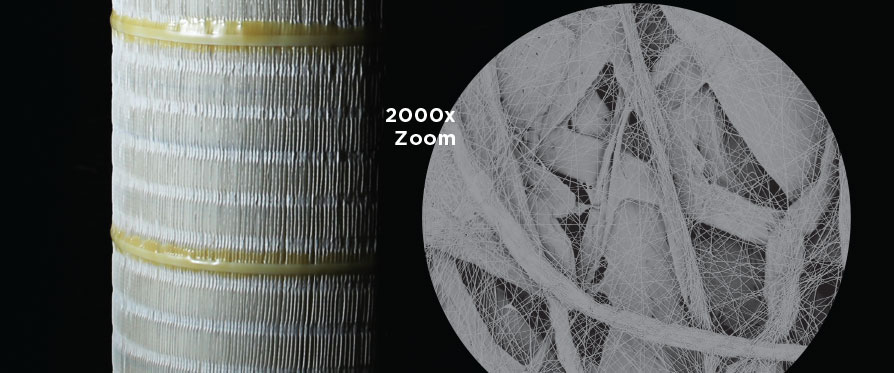

Most Advanced Nanofiber Technology The Nanofiber surface stops sub-micron particles from entering and becoming embedded into the media beneath the Nanofiber

Reduced Operational Costs | Lower Operational Mass Emissions

Less Pulse Cleaning Dust is easily pulsed off of the Nanofiber media because it remains on the surface

Industry’s Best Surface Loading Technology Enhances dust cake release, leading to longer filter life

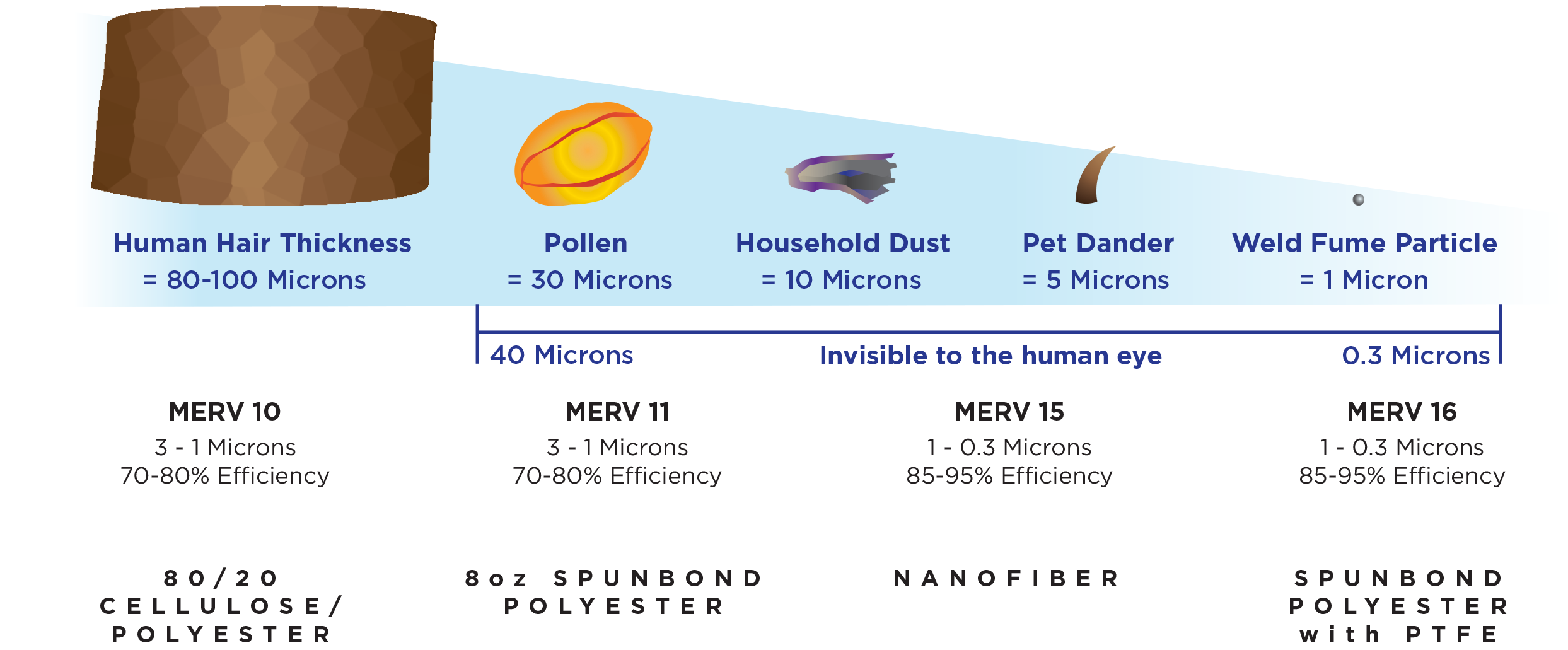

Particle Size & Media MERV Ratings

Filter Media Applications

| Media Description | MERV | General Usage | Max Temp. | Typical Application |

|---|---|---|---|---|

| Nanofiber | 15 | For standard dust applications | 180°F | Blasting, carbon black, powder paint, chemical processing, pharmaceuticals |

| Nanofiber FR | 15 | For applications where there is a possibility of a spark entering the collector | 180°F | Blasting, carbon black, powder paint, chemical processing, pharmaceuticals |

| Nanofiber Open Pleat Spacing | 15 | For applications with large or irregular shaped particles | 180°F | Composite grinding, fiberglass processing, grain handling, paper, tobacco, wood |

| Nanofiber FR Open Pleat Spacing | 15 | For applications with a spark or large or irregular shaped particles entering the collector | 180°F | Blasting, carbon black, powder paint, chemical processing, pharmaceuticals |

| Cellulose/Polyester Blend | 10 | For standard dust applications | 180°F | Blasting, carbon black, powder paint, chemical processing, pharmaceuticals |

| Cellulose/Polyester Blend FR | 10 | For applications where there is a possibility of a spark entering the collector | 180°F | Blasting, carbon black, powder paint, chemical processing, pharmaceuticals |

| Cellulose/Polyester Blend with Open Pleat Spacing | 10 | For applications with large or irregular shaped particles | 180°F | Composite grinding, wood, paper |

| 100% Synthetic Polyester/Fiberglass Blend | 12 | For applications with large or irregular shaped particles | 275°F | Coffee, salt, sugar, cocoa, detergents, stearates |

| 100% Polyester Spunbond | 11 | For applications where coarse particles and aggressive cleaning cycles are needed | 275°F | Powder coating, cardboard, cement, paper, coffee, polishing |

| 100% Polyester Spunbond with hydro/oleophobic treatment | 11 | For applications where high humidity and oil can enter the air stream | 275°F | Metal grinding, textiles, tobacco |

| 100% Polyester Spunbond with PTFE Membrane | 16 | For applications demanding high efficiency or 100% reclaim characteristics | 275°F | Food, pharmaceutical, pesticide, lead, agglomerating material |

| Cellulose/Polyester Blend with PTFE Membrane | 16 | For applications demanding high efficiency or 100% reclaim characteristics | 160°F | Food, pharmaceutical, pesticide, lead, plastic, processing |

Filter Media Applications

| Media Description (swipe left) | MERV | General Usage | Max Temp. |

|---|---|---|---|

| Nanofiber | 15 | For standard dust applications | 180°F |

| Nanofiber FR | 15 | For applications where there is a possibility of a spark entering the collector | 180°F |

| Nanofiber Open Pleat Spacing | 15 | For applications with large or irregular shaped particles | 180°F |

| Nanofiber FR Open Pleat Spacing | 15 | For applications with a spark or large or irregular shaped particles entering the collector | 180°F |

| Cellulose/Polyester Blend | 10 | For standard dust applications | 180°F |

| Cellulose/Polyester Blend FR | 10 | For applications where there is a possibility of a spark entering the collector | 180°F |

| Cellulose/Polyester Blend with Open Pleat Spacing | 10 | For applications with large or irregular shaped particles | 180°F |

| 100% Synthetic Polyester/Fiberglass Blend | 12 | For applications with large or irregular shaped particles | 275°F |

| 100% Polyester Spunbond | 11 | For applications where coarse particles and aggressive cleaning cycles are needed | 275°F |

| 100% Polyester Spunbond with hydro/oleophobic treatment | 11 | For applications where high humidity and oil can enter the air stream | 275°F |

| 100% Polyester Spunbond with PTFE Membrane | 16 | For applications demanding high efficiency or 100% reclaim characteristics | 275°F |

| Cellulose/Polyester Blend with PTFE Membrane | 16 | For applications demanding high efficiency or 100% reclaim characteristics | 160°F |

Let our experienced team select the right filters for your application.

Our Experts on Dust Collector Cartridge Filters

We want to make sure that you get the right SMAC OEM replacement filters for your specific application. So, let our filter experts guide you. They will do more than just cross-reference dust collector filter numbers. They’ll also troubleshoot any filter problem you may be having like short filter life, plugging, or leakage.

Obviously, we want to be your supplier of high-performance filters for the dust collector brand you own. For this reason, our skilled and experienced team will service your needs so you want to keep coming back.

Josh Longmire