Stop Frequent HVAC Filter Replacement

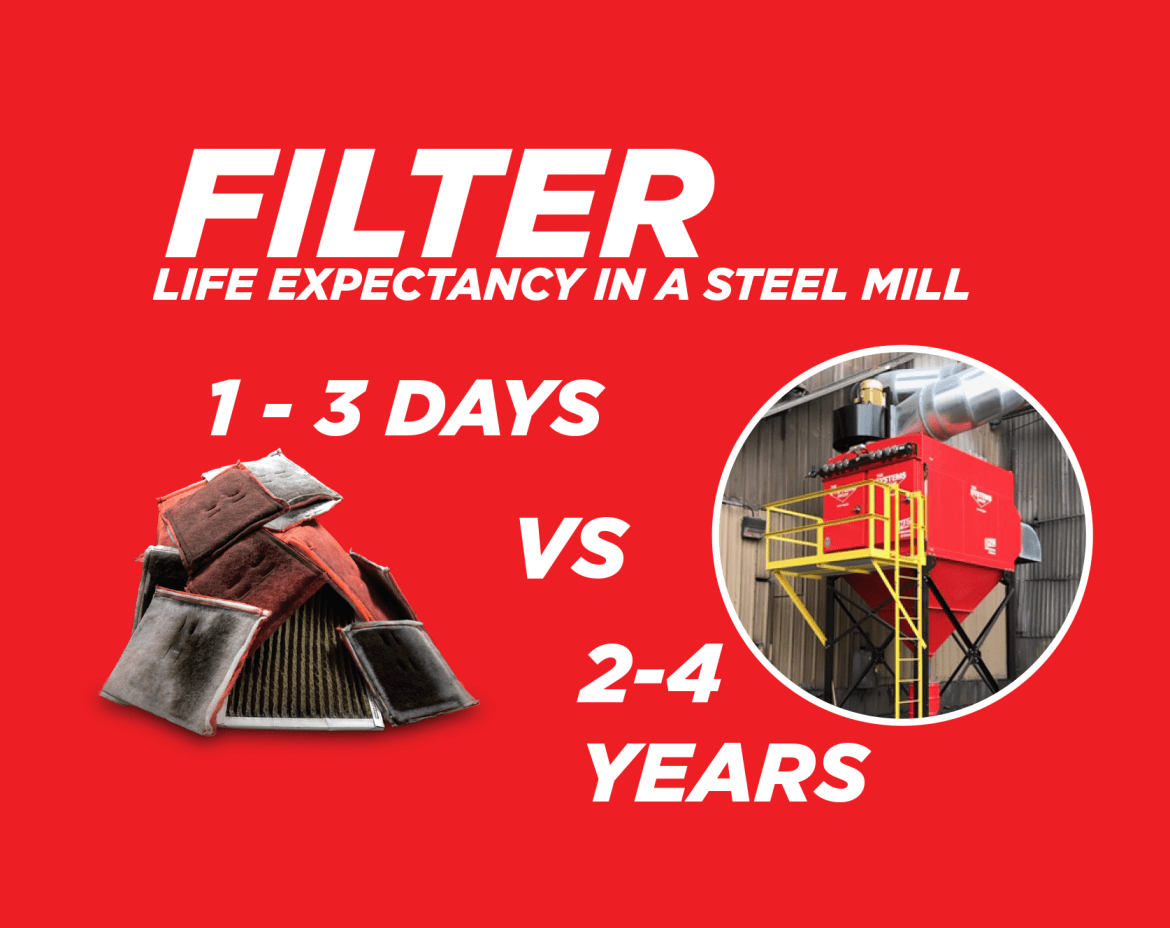

Self-Maintaining Air Cleaner Filters Last Years, Not Days

1000x THE LIFE OF HVAC FILTERS

HVAC FILTER REPLACEMENT IS COSTLY. SMAC THAT!

SMAC Filters are specifically designed for the harsh environments and heavy dust loads found in Steel Mills and all heavy industry. Traditional HVAC filter replacement in these factories is normally weekly, sometimes even daily, more often than not by contract labor.

SMAC industrial air cleaners remove this headache by offering 1000x the life of traditional HVAC filters. By switching to SMAC, your people and equipment will not only be more protected by our Self-Maintaining technology, but you’ll also save on contract labor and filter media disposal costs. As an added bonus for certain applications, throw dust collection drums in an Electric Arc Furnace for material reclamation.

SMAC Applications to End Constant HVAC Filter Replacement and Improve Safety

Transformer Vaults

Keeping conductive dust out of the electrical systems of your transformer vault is critical. Arc flashing can cause a fire and/or explosion, shutting down the whole operation of a melting process. A 30,000-volt transformer can cost multiple millions of dollars to replace. It must be protected from heavy particulate.

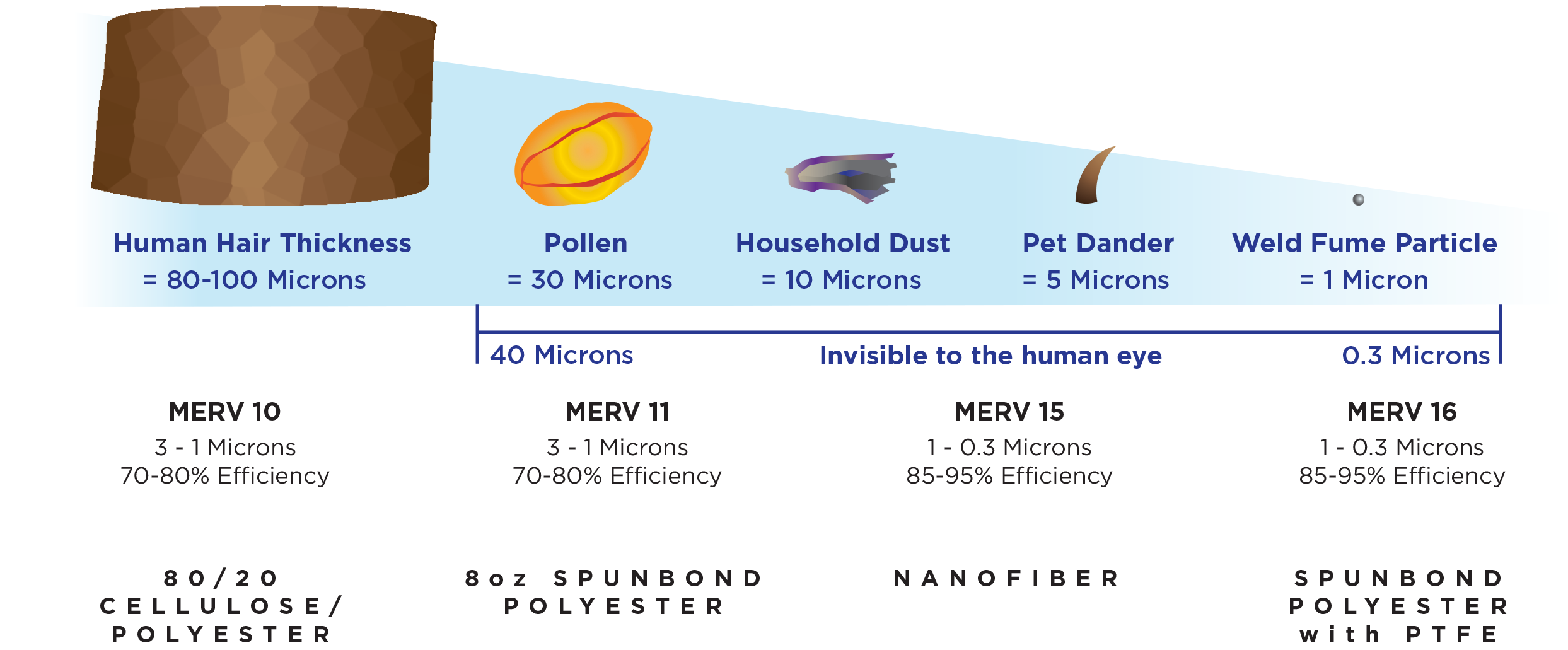

HVAC systems alone are inadequate to protect equipment in transformer vaults. Air conditioning keeps the heat out of the room, but not the dust. Most steel mills try to cool and pressurize a vault with just an HVAC system. They pull outside ambient air into the room, filtering it with MERV 12 or 14 filters, sometimes MERV 8. Dust is able to go right through those filters.

Further, there is no pressurization in the room by just producing airflow through it with an HVAC system. The common practice is to mitigate the heat load from the equipment by releasing it through a louver on the opposite side of the room. The misconception is that this also creates a positive pressure to keep dust from blowing in through opened doors.

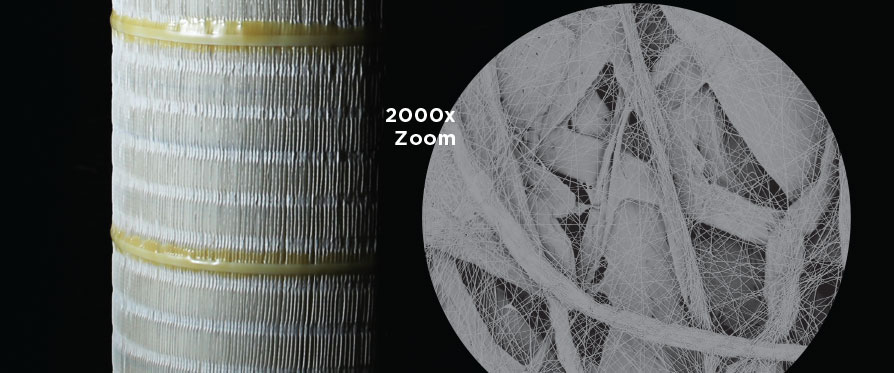

Conversely, the SMAC nanofiber filter captures all the particles with an efficiency of 0.5 micron and larger. We design the system to keep enough pressure in the room so that a sufficient amount of air flows out an open door to keep dust and contaminants out. So, we’re pressurizing the room with clean, filtered air using SMAC technology rather than the old, inadequate way with just an HVAC system.

An HVAC system alone reduces the longevity of transformer vault equipment. HVAC filters cannot handle the heavy dust loading and particle sizes like a SMAC filter system can. Weekly HVAC filter replacement stops with both systems working together.

If you only recirculate the air with a closed-loop air conditioning system, you’re not getting pressurization, which is needed to keep the dust out.

MCC Rooms

As with transformer vaults, motor control center (MCC) rooms have electrical systems that must be protected. Conductive dust can cause arc flash which can destroy equipment. But there’s an added safety danger to personnel. It’s that people are frequently walking in and out of these unlocked rooms. Some even have their offices in them because of the comfortable air conditioning.

Usually, an HVAC system is installed in an attempt to evacuate the heat load from the equipment and provide breathable air. But recirculating the air with a closed-loop air conditioning system is not creating pressurization to actually keep dust out. In reality, doors are constantly opening and closing, and an HVAC system will not keep dust from entering the room.

There’s a common mistaken belief about HVAC systems and the dust found in steel mills. Many think that cooling the room with HVAC filters will do the job. It won’t. The key is to pressurize a room sufficiently to keep dust and contaminants out while allowing the HVAC system to keep it cool.

The SMAC filter does just that. It produces enough positive pressure with clean, filtered air without taxing the cooling system. Using the SMAC system in conjunction with an HVAC system is the best of both worlds. It keeps the MCC room cool while keeping dust out to prevent arc flash issues. Weekly HVAC filter replacement is eliminated because they no longer load up with dust.

With an HVAC system, you’re mostly just doing heat exchange – keeping the heat out of the room but not the dust. It doesn’t solve the problem and still results in frequent HVAC filter replacement.

Operator Pulpits

A pulpit is usually in the dirtiest part of the mill, right in the heart of the smoke and burn of the furnace. It faces extreme challenges for the safety of operators and the protection of computerized equipment in that room.

Because people are always coming and going, dust gets sucked in through the doors of the pulpit. When the doors open, the air conditioning system is pulling the dust in rather than pushing it out. Pulpit operators should not be breathing metal dust.

There’s another safety issue besides breathing. Furnace dust inside the pulpit gets the viewing glass very dirty, obstructing operator view. Therefore, it endangers other employees outside the pulpit. It’s critical that operators be able to view what’s going on out on the deck.

If the pulpit isn’t under positive pressure, there is a lot of dust inside all areas of it. Even the food in a connected break room gets contaminated if left out for a short time.

The SMAC air cleaner provides that positive pressure with clean, high-efficiency filtered air. It works together with the cooling of the HVAC system to keep dangerous dust out. This immensely reduces the dust loading on the HVAC filters, ending weekly changeout.

Trying to control dust with an HVAC system is the old way done for years. Now there’s a far better way that actually works – without weekly HVAC filter replacement.

Crane Cabs

Crane cabs operate where noxious gases and particulates accumulate most in a mill. They typically have their own power source with an HVAC system circulating cool air through the cab. But due to the heavy dust loading in this environment, filter changeout is typically every few days.

Moreover, the lack of sufficient positive pressure in the cab allows dust to get inside of it anyway. So, the personal safety of the operator is more at stake than is mistakenly believed. HVAC cools the air but does not keep hazardous dust out of the cab when the door is opened.

SMAC protects both the cab operator and the filters in the HVAC system. It provides hospital-quality air for breathing while keeping dust out. It also greatly increases the longevity of the HVAC system producing the cool air that’s critically needed in the surrounding hot environment. As a result, frequent filter changeout is eliminated.

Also, the electrical components of the crane are not protected from the metal dust that can cause an arc flash. Don’t dismiss cab-less cranes that operate by remote control. That’s because there’s an MCC room on each crane rail since they have their own power. So whether you have a person up there or not, SMAC still protects the electrical components.

An opened electrical cabinet reveals heavy dust accumulation. This hazardous condition can produce an arc flash, which in turn can generate a fire or explosion.

SMAC can work with an existing HVAC system. It actually extends the life of the HVAC filters while providing positive pressure to keep dust and particles out. This puts an end to constant HVAC filter replacement.

Air Compressor Intakes

Air compressors in steel mills are very large and very expensive. Filtration of the intakes is critical so dust particles don’t destroy them. But managing air compressor intakes can be a full-time job with constant filter changeouts.

The first photo (below) is of a common housing arrangement using HVAC filters on the intakes. Dust loads up these disposable filters in only a few days, requiring continual replacement. Plus, this setup does nothing to keep dust out of the compressor room itself.

The second photo is of a SMAC installation for a large air compressor. It is supplying clean, filtered air directly to the compressor intakes. At the same time, it’s putting the compressor room under positive pressure. This prevents dust from entering the room when doors are opened.

You’re tired of the maintenance and upkeep of something that’s not a critical component of your process. Eliminate that with a filter that you change every 2 to 3 years. SMAC filters do away with frequent HVAC filter replacement.

SMAC Filter Options

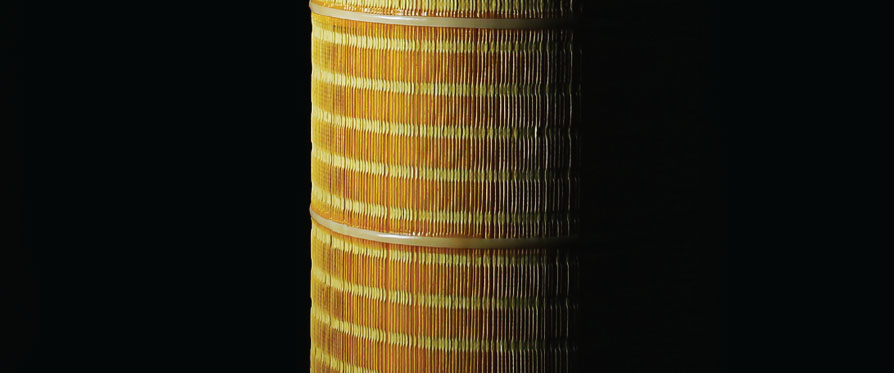

Nano Filters

Nano FR Filters

Spunbond Filters

Most Advanced Nanofiber Technology The Nanofiber surface stops sub-micron particles from entering and becoming embedded into the media beneath the Nanofiber

Reduced Operational Costs | Lower Operational Mass Emissions

Less Pulse Cleaning Dust is easily pulsed off of the Nanofiber media because it remains on the surface

Industry’s Best Surface Loading Technology Enhances dust cake release, leading to longer filter life

“Since purchasing 12 of the SMAC Air Compressor Filter Units, I have saved close to $90,000 on HVAC filter replacement cost over the first 6 months of use.” -Steel Mill Air Compressor Maintenance Supervisor

SMAC Easy Filter Change Out